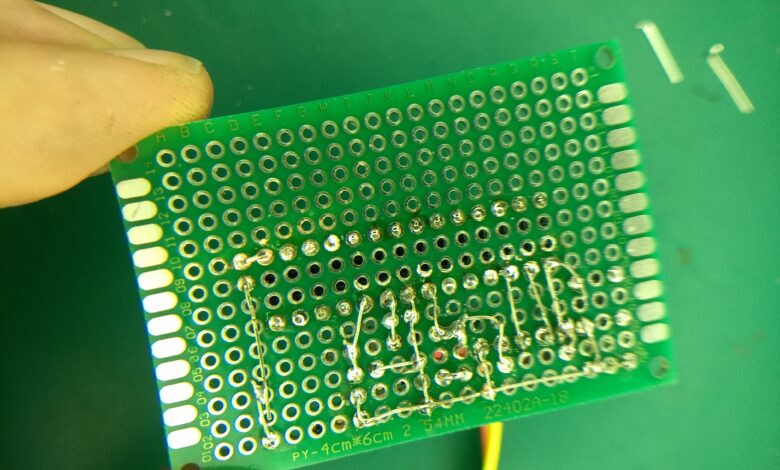

Is Your PCB Prototype Holding Back Your Innovation?

In today’s fast-paced technology landscape, innovation is the heartbeat of progress. Whether you’re designing the next wearable device or breaking ground in aerospace systems, your product is only as good as the infrastructure behind it. At the core of this infrastructure lies the PCB prototype—an essential component that often doesn’t get the attention it deserves.

While many engineers and startups focus heavily on functionality and aesthetics, they sometimes overlook the limitations imposed by poor-quality prototyping. So, if your projects seem to be stuck in limbo or your launch deadlines keep shifting, it’s time to ask the hard question: Is your PCB prototype holding back your innovation?

The Role of PCB Prototyping in Innovation

Printed Circuit Boards (PCBs) are the central nervous system of modern electronics. They provide the mechanical and electrical connections required to integrate components into a functional product. A PCB prototype allows designers and engineers to test and validate circuit functionality before mass production, making it an indispensable part of the development cycle.

But not all PCB prototypes are created equal. A rushed or low-quality prototype can introduce significant roadblocks to innovation, from signal integrity issues and poor component placement to unexpected design failures.

Common Pitfalls in PCB Prototyping

Let’s look at the most frequent issues that can stall your project:

1. Poor Design-for-Manufacturing (DFM) Practices

Design-for-Manufacturing is a critical aspect that often gets overlooked. If your prototype isn’t optimized for fabrication, you might face higher production costs, longer lead times, or even complete design revisions. This is not just inconvenient—it’s a momentum killer. Check over here for DFM guidelines to ensure your designs are production-ready.

2. Inadequate Testing and Validation

Testing is where prototypes prove their worth. Skipping thorough validation can result in errors that remain hidden until the final stages—when they’re the most costly to fix. Make sure your prototyping process includes extensive electrical, thermal, and mechanical testing. This isn’t an area to cut corners.

3. Using Low-Quality Materials

The temptation to cut costs during prototyping is real, especially for startups. However, using sub-par materials can lead to performance issues and mislead your assumptions about the final product. Always source your PCB prototypes from reputable manufacturers. Find out more about suppliers with strong track records and certifications.

4. Limited Iteration Cycles

Prototyping is meant to be iterative. If your current provider takes weeks for every prototype or charges a premium for each revision, it’s time to reconsider. Quick turnaround times and affordable pricing models enable you to test, fail fast, and innovate faster.

How to Spot a Problematic PCB Prototype

If you’re unsure whether your prototype is slowing you down, watch for these red flags:

- Frequent system crashes or overheating

- Unexplained signal loss or interference

- Difficulty in scaling from prototype to production

- Long delays between design submission and delivery

- Mismatch between CAD designs and physical boards

When you recognize these issues, don’t dismiss them as “normal.” They’re indicators that your prototype is not up to the mark. Go right here for a detailed checklist on PCB performance issues that can sabotage your innovation.

The Cost of Holding Back

When your prototype underperforms, the consequences ripple across your entire product lifecycle. You face longer development cycles, missed market opportunities, and inflated costs. More critically, your team may lose confidence, and stakeholders might start questioning your execution capability. In the long run, a suboptimal PCB prototype can cost more than just money—it can cost your competitive edge.

What to Look for in a High-Quality PCB Prototype

Choosing the right PCB prototyping partner can turn your innovation cycle from frustrating to frictionless. Here’s what to look for:

1. Advanced Capabilities

Ensure the manufacturer can handle high-speed signals, HDI (High-Density Interconnect) boards, and multilayer configurations. This flexibility is essential for sophisticated electronics.

2. Fast Turnaround

Speed is everything in innovation. A partner that offers quick prototyping without compromising quality can significantly reduce your time-to-market.

3. Transparent Communication

Your prototyping partner should act as an extension of your design team. Look for vendors who provide real-time feedback, DFM analysis, and collaborative support.

4. Proven Track Record

Before committing, review case studies, certifications (ISO, UL, RoHS), and client testimonials. Don’t hesitate to check over here for industry ratings and third-party reviews.

Embracing Agile Hardware Development

The software world has already embraced agile methodology. It’s time for hardware developers to do the same. Agile hardware development relies heavily on rapid, reliable prototyping and quick iteration cycles. A modern PCB prototype provider will align with this philosophy, enabling you to refine your product as you go, not after you’ve sunk months of work into a flawed design.

Conclusion:

Innovation thrives on agility, precision, and execution. A lagging or inefficient PCB prototype can anchor your project and compromise everything from funding rounds to go-to-market timelines. If you’ve been struggling with technical glitches, elongated development cycles, or rising costs, it’s worth revisiting your prototyping strategy.

The right prototype can serve as a launchpad, not a leash. Whether you’re an ambitious startup or an established enterprise, making smart choices in your PCB development process will pay dividends in innovation, speed, and scalability.

Find out more today by exploring modern PCB prototyping solutions that align with your goals. Go right here to connect with experts who can help turn your ideas into reality—without the setbacks.